It is kinda crazy when you think about it. Here we are on a boat, on a river, with no 'jobs', and nowhere we have to be, nothing we have to do and I can't find time to blog!

There is a lesson here somewhere. I'll think about it later and get back to you…

The work continues to make Yume ready for sea. We bought her having been told the mechanics were good and really all we needed was the cosmetics. Right. I guess everyone's idea of good is different.

This week has been spent on a couple of projects that seem to get more complicated as they grew on their own.

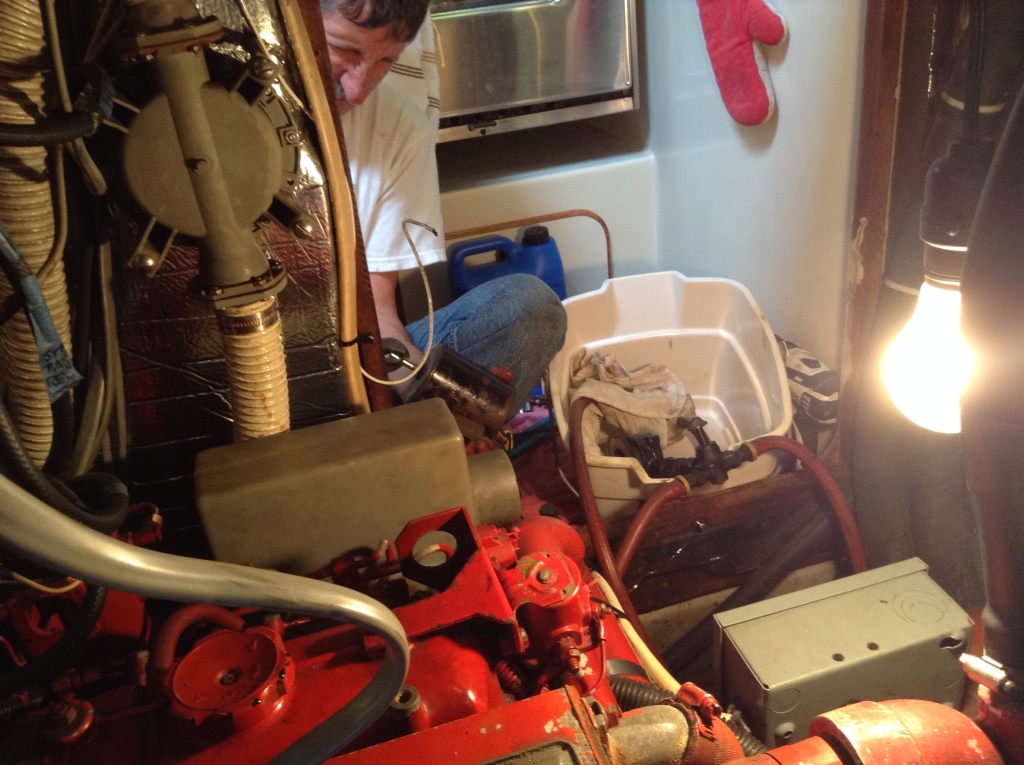

This is the “engine room' which is basically a fiberglass box molded into the hull, with a few cut outs for access that would be perfect if I was about two and a half feet tall. Most of this week has been spent in or half out of the “room”.

1. To change the engine and generator oils took 3 days. What was supposed to be a simple job of using an electric oil pump to suck out old oil and pump new oil back in didn't exactly pan out. The first two hours was spent taking apart the frozen pump and fixing that, then taking apart the reversing switch to find it corroded so badly it had to be replaced. Then when the pump was finally free, there was no hot wire to be found. The ground was right there but no feed. What the heck? So new wiring had to be run. THEN I could change the engine oil but for some reason the generator oil would not suck out no matter what I did. That took all day Tuesday.

Of course Ryan is hard at work in his cabin doing his online schooling (or playing video games if I am not checking him!)

On Wednesday we needed to get a wifi extender system installed to boost the marina wifi so we could use it on board. This is supposed to pick up and boost signal from wifi stations up to two miles away. I built a housing for the antennae and radio booster from PVC pipe and mounted in up on the mizzenmast forestay and ran the cat5 cable to a cabinet. Here 110v outlet from the inverter was needed for the power supply to the antennae and the wireless router. It took me almost four hours to get the damn thing programmed. That ended up being a 10 hour project and costing $150 but who is counting?

Then it was back to the engines. This time to track the pump issue I needed to take off all the tie wraps and connectors for half of the wiring and piping in the place. While I was doing that I had access (I was already half under the motors in the bilge) to the piles of nasty, oily, debris in the bilge so I dove into that too. We can actually see the bottom of the bilge now!

Then the salt water strainers needed cleaning and a bolt broke off as soon as I started removing those.

I could go on for another couple of days (and did) but you get the idea.

We knew that by buying an older boat we would be doing this stuff – and I am not complaining at all. Aside from the oil and grime under the fingernails and the sore muscles in places I did not know I had muscles, I am so thankful I have the abilities to know what I am doing, the boat to do it with, the time in which to make it happen , and the support and help of Shelly to get through it.

And in the end I will know every wire, every hose, every part of this floating assembly of parts that we call home and are about to take to sea to God knows where!

By the way, the feed burner has screwed up somehow so if you signed up to get notification it may not be working. I hope to get to that today as soon as I get the generator fuel filter changed. It should only take me a couple of minutes. 😉

Leave a comment. Our friend Steve let me know I did not have it enabled so I did fix that…