by miami | Nov 29, 2013

Putting up a first sail on Yume

We put up a sail today. This is a big deal! Had the boat a month and finally got to go out. Not far, no wind, but nothing bad happened either!

We did discover that the chart plotter would not come on ( found out later some idiot hooked the power wire to the gauge light switch), and that the knot meter did not work ( Ryan learned how to take it out while in the water and clean it), and we learned that the genoa unfurls and furs quite nicely.

She ran a bit slow but methinks the beard and barnacle on the bottom have a lot to do with that. The revs were running very high as well but that could be dirty bottom and/ or wrong size prop. I would not be surprised if the prop were incorrectly sized at all.

A diver is coming this weekend to clean the bottom, check the zincs and the prop…

After a nasty couple of days, Thanksgiving started cold (ice on the dock) but once the sun came up it was a glorious day. We started looking for the leaks (think the screws in the rub rail need rebedding) and cleaned the hull a little.

I replaced the propane solenoid first thing only to find some idiot (me) had ordered the wrong voltage so it had to be taken back out and the old one cleaned up and replaced so the bird could join us for dinner!

And what a first dinner it was!

The best part of the day was definitely going out though. We only have a few more days here as we have to be in west palm beach DEC 20 which is 525 miles away. Since we only do 6-7 miles an hour, and can run about 10 hours at most a day we have to get moving!

Ryan got a 6′ cast net and was out as soon as the weather cleared learning how to throw it, and I got up on the bow to test the anchoring systems.

We are all excited to get moving on. Settling down to routines on the boat and learning how to manage three people and one dog in 41 feet is actually easier than we thought. In fact it feels like we have always been here.

Getting more work done online too!

Plus you just can’t beat those views off the back deck!

by miami | Nov 24, 2013

Freshly finished woodwork aboard Yume

It has been a busy last several days as parts are delivered daily, more things torn apart to be fixed, pieces of wet varnished wood everywhere drying and a deadline to leave looming.

The new counter top in the aft head has four coats of varnish and was put in yesterday for the last coat before the ugly weather due today. All the teak trim looks beautiful and this will be assembled by end of day today!

Of course we found another small leak yesterday behind that boxy looking fiberglass above the top which holds the two propane tanks in the deck topside that had to be found and fixed.

My mechanic friends will appreciate how pleased I am with being organized. Tools in easy to reach places, shelves where they are needed, hardware sorted and organized, and everything neat and properly stowed for sea and work.

Another issue that popped up was when we started the air conditioning system the first time on Monday and heard a loud grinding noise that said you have problems! The sea water pump that cools the system had to be removed, taken out to the dock and disassembled. The pump was having none of that and after about an hours of using every trick I knew I took it to Savannah and paid someone $90 to get it apart only to find out it is only useful as an anchor.

It only took one day and $235 to get this new replacement that is half the size, very quiet and fits in perfectly. The old pump took up the whole bottom of the shelf and was a huge bronze monster. The heat is appreciated this morning as old man winter is howling outside! That shiny thing to the right of the red pump is a sea water strainer. Of course it had to be taken out and serviced too!

Late yesterday we got the faulty oil pressure gauge at the helm replaced so I know the engine has oil pressure , and a backup mechanical gauge in the engine room. I am tickled pink, and as soon as I get a diode in the alternator ignition wire to work correctly we will be ready for sea trials.

We plan on dropping and raising the anchors a few times here at the dock to test the systems and teach Ryan how to do this very important job. We’ll run the engine a lot today at the dock.

We also built a nice long shelf for Shelly in the galley over the freezer/fridge that goes in today. That’s the shelf drying under her new food storage netting.

And last but not least, we sold our last vehicle yesterday, our favorite ever vehicle the red f250 which has been with us almost the whole High Country Stables journey. Our boys grew up traveling in this truck, and many young Shelly proteges rode to horse shows in this truck. We are super happy to sell as it replenishes our cruising kitty, but we are now vehicle-less. No insurance, no stopping for gas, no auto repairs, and if we want something from the store we must ride our foldable bikes, walk, or beg, borrow, steal or rent a vehicle!

Fine with me!

Our congratulations and best wishes to our niece Kim who woke up this morning a married woman! So sorry we could not make it, and offer you and Tim a berth when you are ready to come visit. Pre kids that is 😉

by miami | Nov 18, 2013

Saturday I was sort of excited. I had new alternator and a new water pump on the main engine and was looking forward to a trial run with any luck.

We just needed a it of tweaking here and there and we'd be off for a boat ride!

It took all day Saturday to figure out that the alternator was missing a diode that was causing voltage to back flow through the ignition system and creating a bit of havoc. Plus the engine shut down alarm quit working at the same time which really messed me up. Thanks to my buddy Steve for some long distance troubleshooting help.

Of course no one in this little village would have the parts but the rum store was open…

Sunday morning Ryan washed all the dog hair off the boat and we found water in the aft bath (head in nautical terms) which meant removing the cabinet I built (see week 1) to find the leak. It turned out some previous owner (PO) had 'fixed' a hole with a minimal amount of caulk which was under a hinge on the deck. The hole and the holes around it got drilled out clean and epoxied correctly.

However now that the cabinetry was all out Shelly decided to go ahead, sand, and start varnishing all the wood.

I am down there cleaning up when we decided we needed to go ahead and fix the counter top while it was open as the PO had let aforesaid leak rot the wood and the counter looked kind of crappy. Of course that turned into a several hour job and required a trip to Savannah today for a full sheet of hardwood plywood to replace the top. It sure will look nice though!

This morning it was a it warm and muggy so Shelly suggested we turn on the AC and just dry the boat out a bit. He sea water cooling pump make such a screech when we turned it on I just hung my head. Here we go again. I got it out ok, but the bolts holding the pump to the motor were so corroded I had to take the whole thing to Savannah and find someone to get the bolts out! It's still there..

So we got back about three with parts for the alternator, oil pressure switch, bilge pump, plywood, new toilet seat, paint for the places we have all open now, epoxy for the holes, a new saw to cut the plywood correctly, and more groceries!

This boat living is expensive so we are open to donations from the rich working friends we used to have!

Hopefully we can start putting stuff back together tomorrow as the weather is changing and we really need to head south.

Ian called today and is announced he passed his tests for Combat Control Selection. We are very proud of him for sticking with something that most won't do. He is planning to fly to Florida over Christmas and visit.

I sure hope we get there!

by miami | Nov 15, 2013

One of the true lessons in life is to really understand that every day cannot go perfectly as you would like.

In fact, we need 'bad' days to make the 'good' days appear good! And I believe every day is perfect.

I remembered this last night after heading for bed. The last few days we seem to be going backwards a bit.

First, while troubleshooting the generator, I realized the field windings were bad, meaning we do not have a generator for 110 power off the dock until we can get some where and some funds to tear the whole thing out of the hole and fix or find a used one. That round red piece with the electrical box is the generator… I have come to know it well…

Then I found the fresh water pump on the main engine had been spraying water all over everything for quite some time. They are very hard to find. I finally found one in Miami for only $280. That is the hole it goes in. Ryan and I are having tons of fun cleaning all the rust and grime off every part we can reach. His homeschooling includes diesel mechanic and electrical generation 101. The. Spray had reached the alternator which meant a replacement for another $150. (And since it is such a vital part it meant a spare as well!)z

Then in the middle of all that our new wifi extender system stopped access to the internet. We could see the internet was working but pages would not load. After 5 calls to the router help support in India they do not have a clue and say they will get back to us..

By mid morning yesterday we started getting calls about websites being down. After 6 hours on thehone with godaddy advanced tech support they told me it was my problem not theirs!

But then Ryan caught his first fish – a nice 5 or 6 pound sheepshead off the dock. We had an impromptu fish cleaning class and enjoyed a very nice fish dinner last night!

So we start today very grateful for our blessings, our friends and our family and the fact that we do not have to get in the car and go to work!

by miami | Nov 10, 2013

Sunday evening sitting in the cockpit and remembered it's Veterans Day. Tried to put up our flag but it will take a couple of more rums before I can fly out to the end of the mizzenmast boom…

Thank you to all who have served.

by miami | Nov 9, 2013

It is kinda crazy when you think about it. Here we are on a boat, on a river, with no 'jobs', and nowhere we have to be, nothing we have to do and I can't find time to blog!

There is a lesson here somewhere. I'll think about it later and get back to you…

The work continues to make Yume ready for sea. We bought her having been told the mechanics were good and really all we needed was the cosmetics. Right. I guess everyone's idea of good is different.

This week has been spent on a couple of projects that seem to get more complicated as they grew on their own.

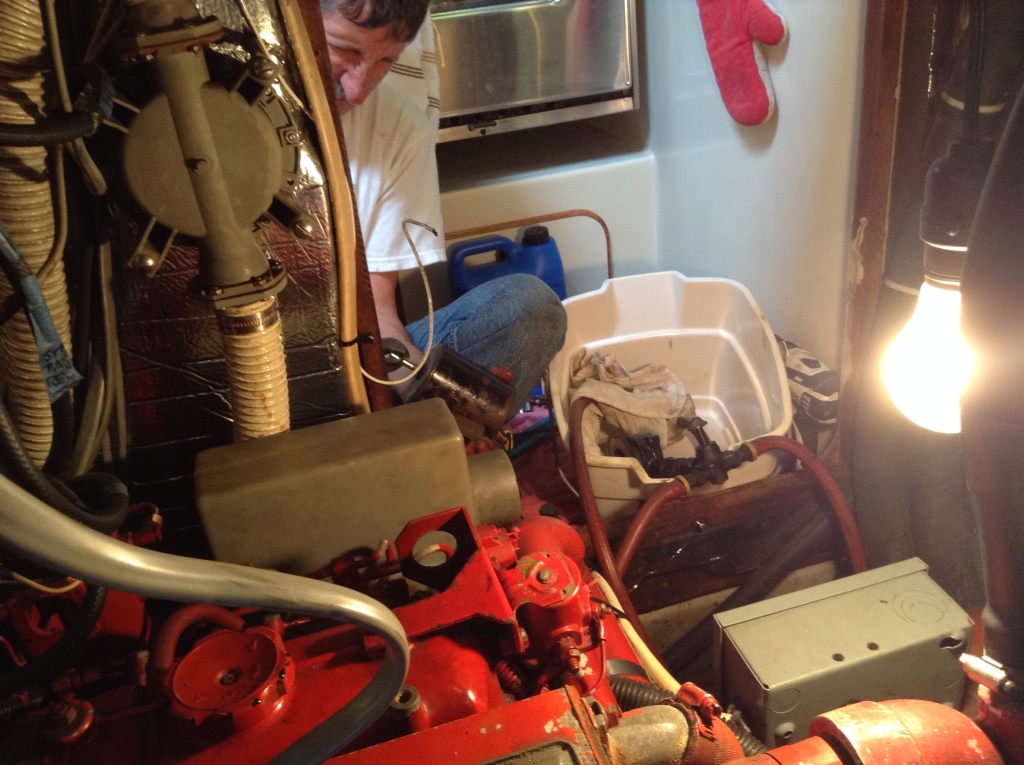

This is the “engine room' which is basically a fiberglass box molded into the hull, with a few cut outs for access that would be perfect if I was about two and a half feet tall. Most of this week has been spent in or half out of the “room”.

1. To change the engine and generator oils took 3 days. What was supposed to be a simple job of using an electric oil pump to suck out old oil and pump new oil back in didn't exactly pan out. The first two hours was spent taking apart the frozen pump and fixing that, then taking apart the reversing switch to find it corroded so badly it had to be replaced. Then when the pump was finally free, there was no hot wire to be found. The ground was right there but no feed. What the heck? So new wiring had to be run. THEN I could change the engine oil but for some reason the generator oil would not suck out no matter what I did. That took all day Tuesday.

That red engine is the Westerbeke generator which gives us lots of electricity to charge batteries, run the refrigeration system, and even run air conditioning ( and heat). The main engine is just to the right (aft) in this box.

Of course Ryan is hard at work in his cabin doing his online schooling (or playing video games if I am not checking him!)

On Wednesday we needed to get a wifi extender system installed to boost the marina wifi so we could use it on board. This is supposed to pick up and boost signal from wifi stations up to two miles away. I built a housing for the antennae and radio booster from PVC pipe and mounted in up on the mizzenmast forestay and ran the cat5 cable to a cabinet. Here 110v outlet from the inverter was needed for the power supply to the antennae and the wireless router. It took me almost four hours to get the damn thing programmed. That ended up being a 10 hour project and costing $150 but who is counting?

Then it was back to the engines. This time to track the pump issue I needed to take off all the tie wraps and connectors for half of the wiring and piping in the place. While I was doing that I had access (I was already half under the motors in the bilge) to the piles of nasty, oily, debris in the bilge so I dove into that too. We can actually see the bottom of the bilge now!

Then the salt water strainers needed cleaning and a bolt broke off as soon as I started removing those.

I could go on for another couple of days (and did) but you get the idea.

We knew that by buying an older boat we would be doing this stuff – and I am not complaining at all. Aside from the oil and grime under the fingernails and the sore muscles in places I did not know I had muscles, I am so thankful I have the abilities to know what I am doing, the boat to do it with, the time in which to make it happen , and the support and help of Shelly to get through it.

And in the end I will know every wire, every hose, every part of this floating assembly of parts that we call home and are about to take to sea to God knows where!

By the way, the feed burner has screwed up somehow so if you signed up to get notification it may not be working. I hope to get to that today as soon as I get the generator fuel filter changed. It should only take me a couple of minutes. 😉

Leave a comment. Our friend Steve let me know I did not have it enabled so I did fix that…